studio rekabentuk

DESIGN studioLOCATION

Blok C23 Level 5

School Of Mechanical Engineering

Faculty of Engineering

Universiti Teknologi Malaysia

OPEN HOURS

Sunday – Wednesday : 8am – 5pm

Thursday : 8am – 3.30pm

Break time : 1pm – 2pm

CONTACT US

07-5534722

EMAIL US

@utm.my

OUR TEAM

ACADEMIC- LAB COORDINATOR

Lecturer

Ts Khairul Anwar Hanafiah

Department of Applied Mechanics & Design

LAB STAF

Assistant Engineer J29

Suriati Bt Kassim

ksuriati@utm.my

ABOUT US

DESIGN STUDIO

Design Laboratory was located under the Applied Mechanics & Design Department of the School of Mechanical Engineering.

This lab currently supervised by Ts. Khairul Anwar Bin Hanafiah as the Lab Academic Coordinator. An assistance engineer has been positioned to ensure the smoothness of the lab operations. We have 3D Printer Machines to perform the activities of designing a material for project and research purposes.

Under the design lab, there are 5 studios for teaching class sessions and design workshop .

Lab Location : C23-507-02

Studio Location : C23-502, C23-503, C23-504, C23-505, C23-506

Workshop Location : E07-01, E07-02

EQUIPMENT

3D PRINTERS MACHINES

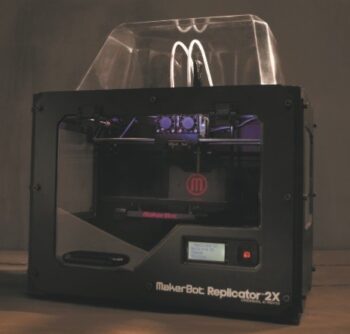

MakerBot Replicator 2X

Material type- ABS filaments

Build volume – 24.6cm x 16.3cm x 15.5cm

Filament Diameter – 1.75mm

Nozzle Diameter – 0.4mm

Connectivity – SD card

File Type – STL

www.makerbot.com

3D PRINTERS MACHINES

Flashforge Creator Pro

Material type- ABS filaments & PLA Filaments

Build volume – 23cm x15cm x 15.5cm

Filament Diameter – 1.75mm

Nozzle Diameter – 0.4mm

Connectivity – SD card

File Type – STL

www.flashforge.com

ABS / PLA (Acrylonitrile Butadiene Styrene)

The most common materials for FDM is ABS and PLA.

ABS (Acrylonitrile Butadiene Styrene)

ABS plastic is made out of oil-based resources and it has a much higher melting point than PLA plastic. It’s also stronger and harder. Because of these particular features, ABS is widely used for purposes ranging from car bumpers and motorcycle helmets to musical instruments, golf-clubs and Lego.

Pros:

Good strength

Goodtemperatureresistance

Very sturdy and hard

Suitable for machine or car parts

Higher melting point

Longer lifespan

Cons:

Made out of oil, so more damaging to the environment

Easy to warp -deforms when not being print on a heated surface

Hot plastic fumes when printing

More difficult to print

Not suitable for using with food

PLA (poly lactic acid)

PLA is a bio-degradable type of plastic that is manufactured out of plant-based resources such as corn starch or sugar cane. This is why it is called ‘the green plastic’.

Pros:

Excellent visual quality

Easiertoprint

Can be printed on a cold surface

More environmental-friendly

Shinier and smoother appearance

Smells sweet when being print

No harmful fumes during printing

Higher 3d printer speed

More detail

Cons:

Can deform because of heat (like a cassette in a car)

Less sturdy (than ABS)

TEACHING LAB

EXPERIMENT / SUBJECT OFFERED

Text

Services

What We Can Do For You

List of your Lab Projects

TEST

Test

TEST

Test