Materials Engineering Laboratory

facilitiesFESEM

FESEM is a versatile analytical ultra high resolution that extends imaging and analytical resolution beyond previously achievable limits. It has a unique variable pressure capability that enables the user to examine a variety of non-conducting samples without time consuming preparation.The equipment is well suited for failure analysis, process control and analytical applications. It has a superior resolution in VP mode of up to 2nm at 30kV with high probe current (up to 20nA) and high stability better than 0.2%/h for analytical applications.It also has a unique in-lens detector for clear topographic imaging in high vacuum mode.

VPSEM

The variable pressure scanning electron microscopy (VPSEM), Model Hitachi S-3400N equipped with the energy dispersive spectroscopy (EDS) is capable to study of wet, oily, and/or non-conductive samples without metal coating or other complicated specimen preparation techniques. It has better electron optics, larger specimen chamber, faster, cleaner evacuation system and fully automated software are just a few of the new features of the S-3400N. Due to a newly designed TMP evacuation system, no cooling water is necessary. It takes less than 100 seconds to exchange a specimen and 6 minutes to reach ready status from a cold start. It requires only 2.0kVA for the power supply. The S-3400N will be a new world standard in the middle class Variable Pressure SEM.

IMAGE ANALYSER

Buehler’s Image Analysis system provides advanced image editing, enhancement and analysis. The program contains both image enhancement features found in conventional image editors plus a number of advanced features not even available in professional photo suites. Quantitative image analysis is a qualification of the features within the simple image, and these features are identified by the contrast difference they have to their surroundings. Mostly this contrast difference can be seem as difference in gray level in a monochrome image. The machine works with the greyscale of an image by digitising it into 256 level.

Sample Preparation Facilities

The Materials Engineering Laboratory offers comprehensive equipment for the preparation of metallographic specimens, facilitating the accurate determination of a material’s microstructure. This process typically involves sectioning, mounting, coarse grinding, fine grinding, polishing, etching, and microscopic examination. The facilities related to sample preparation are precision cutter, hot/cold mounting machine, grinding and polishing machine, and optical microscope with maximum magnification of 500.

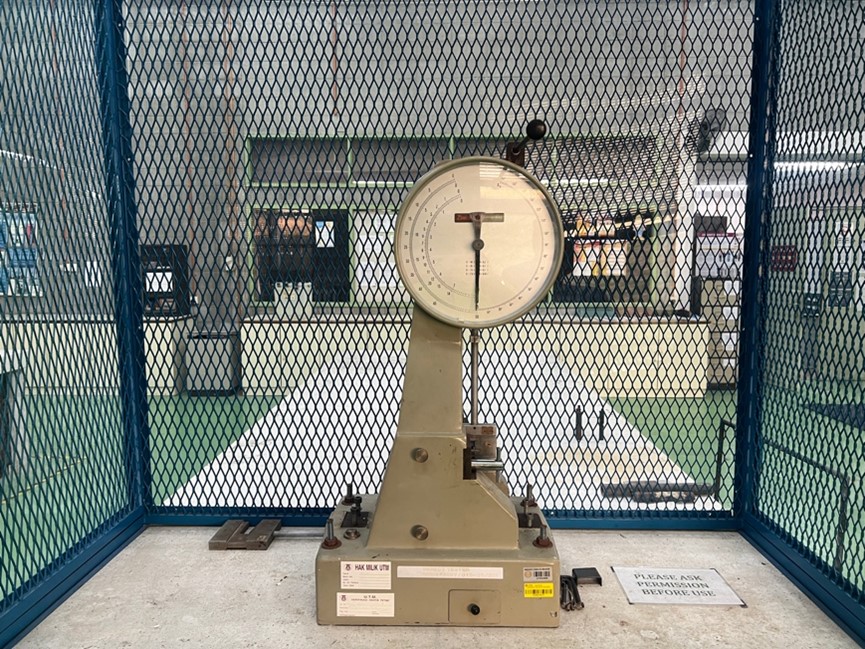

Mechanical Properties Testing

To evaluate mechanical properties of a materials, hardness and impact tests are widely employed to assess the hardness, toughness, and durability of materials. Hardness is a fundamental property that defines a material’s resistance to indentation or scratching. The hardness of a material is often correlated with its strength and wear resistance. One of the most common methods for hardness testing is the Rockwell and Vickers hardness test, which utilizes a mechanical testing machine designed for this specific purpose. Impact testing evaluates a material’s ability to absorb energy during sudden loading, providing critical information about its toughness and resistance to fracture. The Charpy and Izod impact tests are commonly used, and mechanical testing machines designed for impact testing are essential for precise and reliable results.